Tejaswi Renewable Energy offers a performance-driven Steam Fuel Ratio Based Biomass Fuel Supply model designed to optimize fuel consumption and improve boiler efficiency for steam-intensive industries. This service focuses on supplying the right quantity and quality of biomass fuel based on actual steam generation requirements, ensuring predictable output, reduced fuel wastage and stable boiler operations.

Our fuel supply planning is based on detailed steam-to-fuel ratio analysis, ensuring optimal combustion efficiency and predictable steam generation. This approach helps industries control fuel consumption, reduce wastage and maintain steady boiler performance.

What is Steam Fuel Ratio Based Biomass Fuel Supply

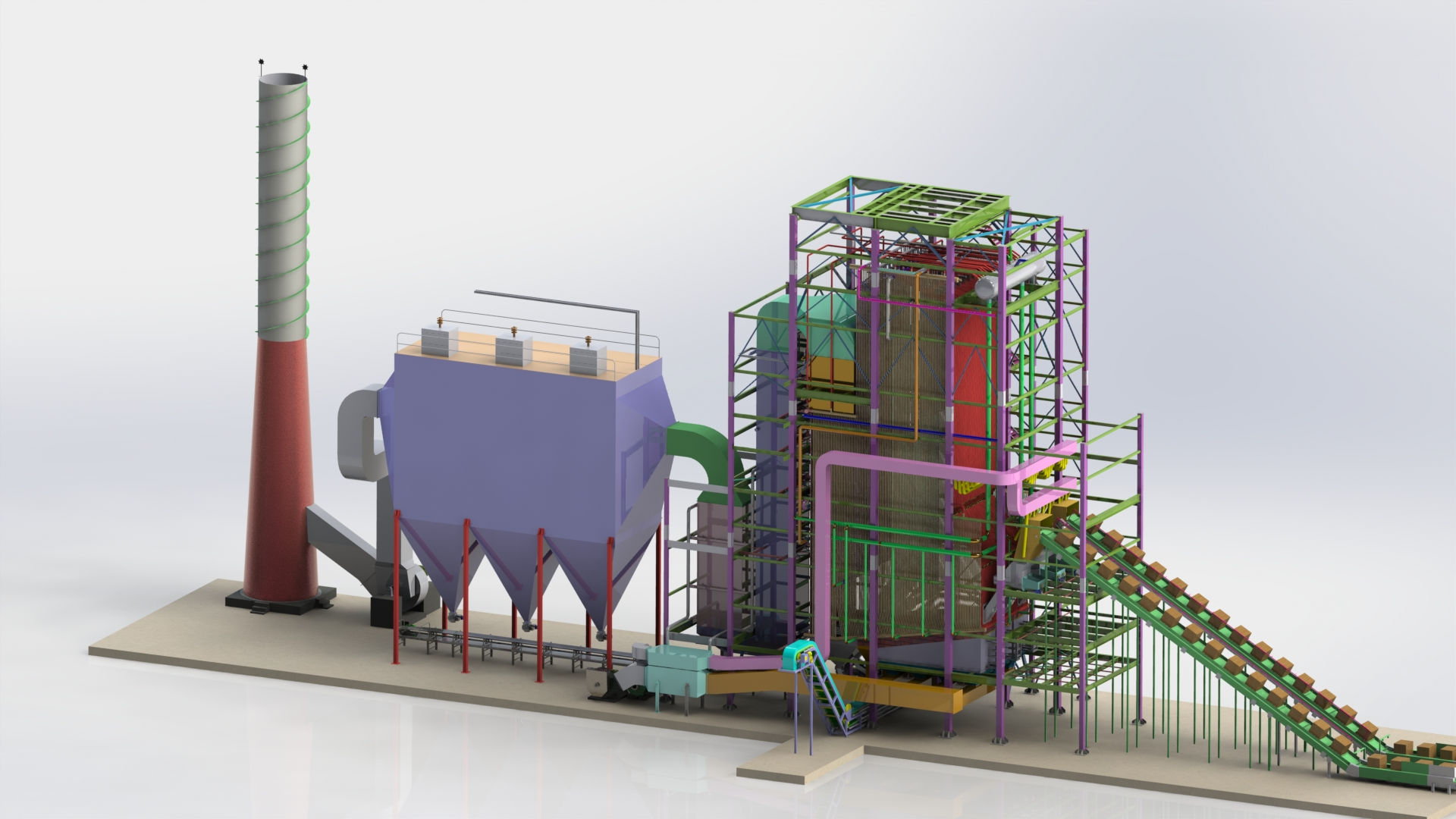

Steam Fuel Ratio Based Biomass Fuel Supply is a structured fuel management approach where biomass supply is planned according to the steam output required by the boiler. Instead of a generic fuel supply method, Tejaswi Renewable Energy analyses boiler parameters such as capacity, operating pressure, efficiency and process demand to determine the optimal fuel-to-steam ratio.

This data-driven approach ensures that the supplied biomass fuel supports stable combustion, reliable steam generation and long-term boiler health. By aligning biomass fuel supply directly with steam demand, industries can achieve consistent thermal performance while controlling energy costs and maintaining production continuity.

How Our Model Works

Our process begins with a detailed assessment of the client’s boiler system and steam consumption pattern. Based on this evaluation, we design a customized fuel supply plan that ensures:

- Correct fuel quantity aligned with steam load

- Consistent calorific value and moisture control

- Stable combustion and reduced heat losses

- Predictable steam output during peak and non-peak operations

Fuel deliveries are scheduled to maintain uninterrupted boiler operations while minimizing excess inventory and handling issues.

Key Benefits

- Optimized fuel consumption and cost control

- Improved boiler efficiency and combustion stability

- Reduced fuel wastage and ash generation

- Consistent steam output supporting production targets

- Lower operational stress on boiler equipment

- Better planning of fuel inventory and logistics

Fuel Quality & Performance Control

All biomass fuels supplied under this model are tested for calorific value, moisture content, density and combustion behaviour. Maintaining uniform fuel quality is critical to achieving the targeted steam-to-fuel ratio and ensuring reliable boiler performance over extended operating cycles.